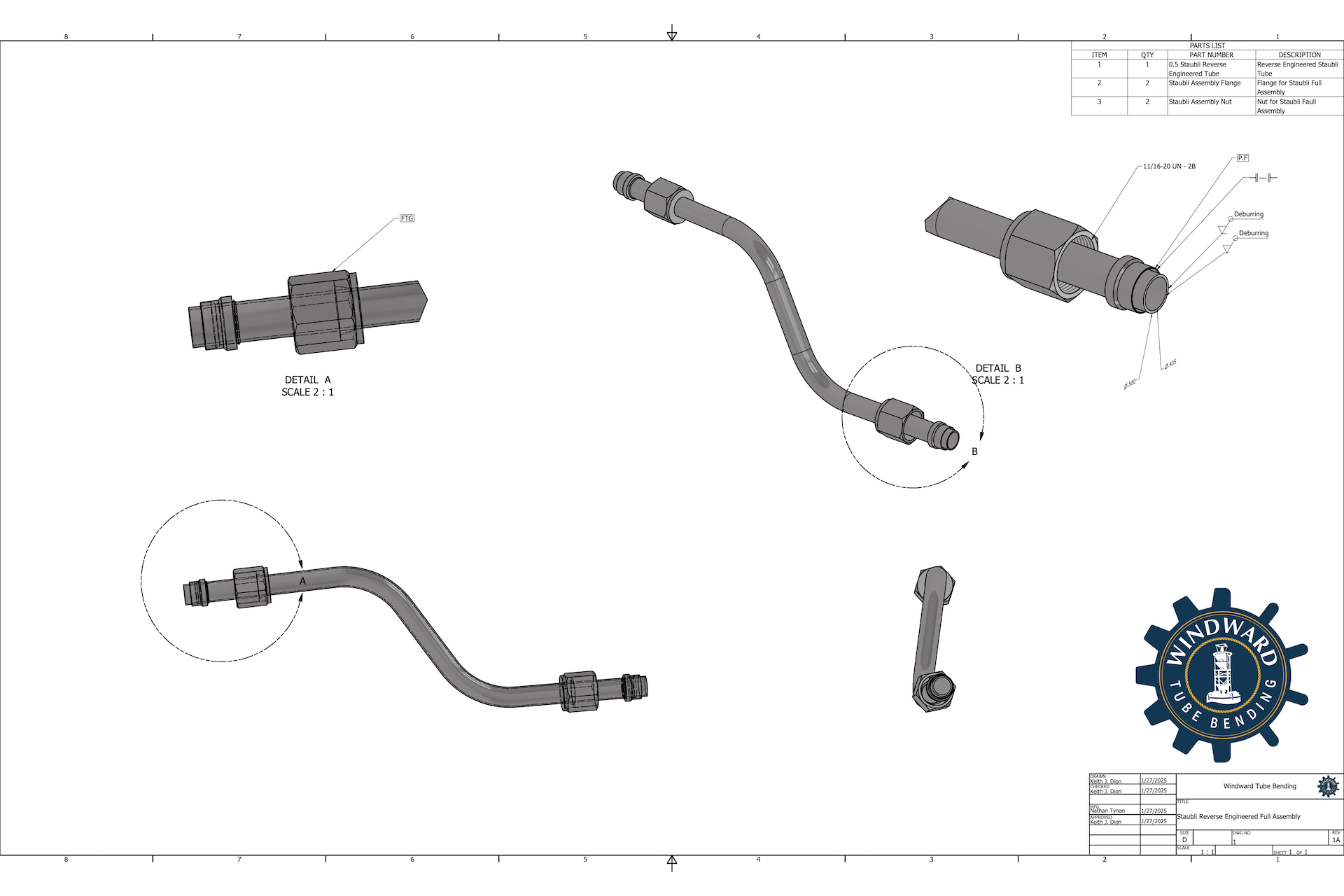

Welcome to Windward Tube Bending

At Windward Tube Bending, we’re excited to announce the expansion of our operations with a new 21,000 sq. ft. facility at 1070 County St., New Bedford. This dedicated space for tube bending manufacturing allows us to significantly grow our existing hydraulic hose, fittings, and adapters business. With this expansion, we’re now able to offer faster turnarounds, superior precision, and a broader range of services, including the ability to scan and recreate your existing parts or fittings with unparalleled accuracy.

Expanding Precision and Capability

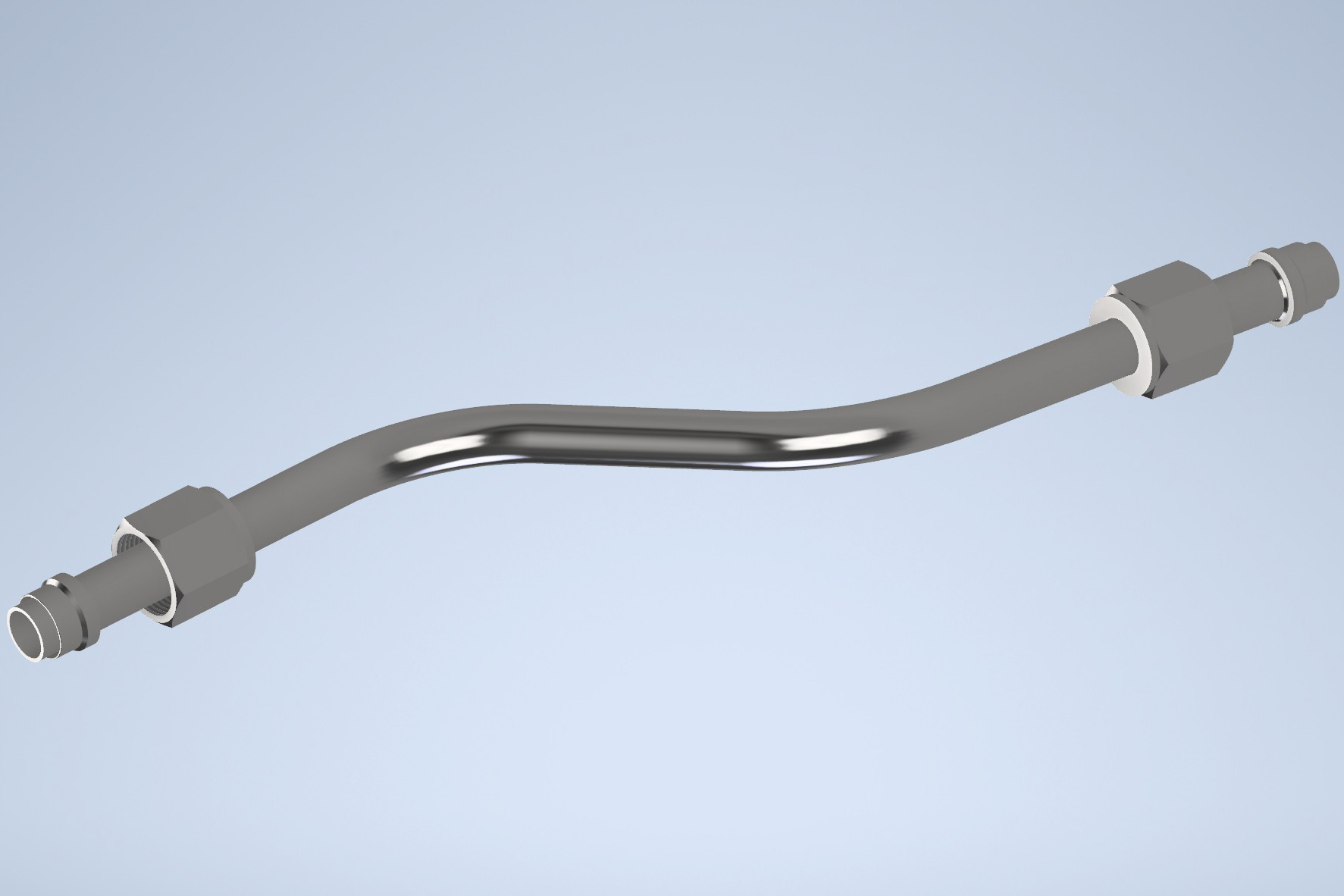

Our state-of-the-art 3D scanning technology enables us to reverse engineer any part or fitting, whether it’s from your existing inventory or a custom design, ensuring a perfect match for your specifications. Whether you need exact replacements, design enhancements, or completely new parts based on your current products, Windward Power has the technology and expertise to deliver.

State-of-the-Art Equipment to Serve You Better

Horn CNC Tube Bender

See separate Word document for full specs.

Scotchman Coldsaw & Ironworker

Hexagon Absolute Arm V2P, 8330, 7-Axis

Olsen Model 50 Powered Heavy Duty Flaring Machine

Haberle Deburring Machine

Uniflex HM225 160-Ton Hose Crimper

Hydrostatic Test Table

Cleanliness Capability to ISO 23309:2020 (Level 15/15/12)

Full Suite of AutoCAD

Why Choose Windward Power?

Precision Engineering: From scanning and reverse engineering to high-quality tube bending and machining.

Increased Capacity: With our new 21,000 sq. ft. facility, we have room to handle larger projects and deliver on time.

Part Recreation & Enhancement: We can scan your existing parts or fittings and recreate them with accuracy—whether you’re replacing an old part or improving a design.

Enhanced Services: Our expanded capabilities allow us to meet all your manufacturing needs.

Commitment to Quality: With advanced equipment and high-quality standards, we ensure that every part meets expectations.